PR

ENGINEERING

WORKS

Powering Industry with

Purpose Since 1960

63+ Years

Industry Experience

Steel & Iron

Expertise in Shaping

Quality Focus

Production & Satisfaction

Global Trust

Trusted by Industries

Our Manufacturing Legacy

Founded in 1994 (with roots dating back to 1960), P R Engineering Works (PREW), led by Mr. Vishavajit R. Jagtap, is a dynamic multi-division group with interests in Manufacturing, Foundry, and Trading. With operations across Maharashtra and a global presence in Asia, America, Europe, and Thailand, PREW is committed to delivering high-quality, precision-engineered products tailored to industry needs.

We are proud to be certified by TÜV NORD, demonstrating our commitment to international standards of quality and excellence in manufacturing. This certification reflects our dedication to delivering reliable and high-quality products.

Our Impact in Numbers

Delivering excellence across global markets

Sectors We Serve

We deliver precision-engineered solutions across diverse industrial sectors, ensuring performance, durability, and efficiency.

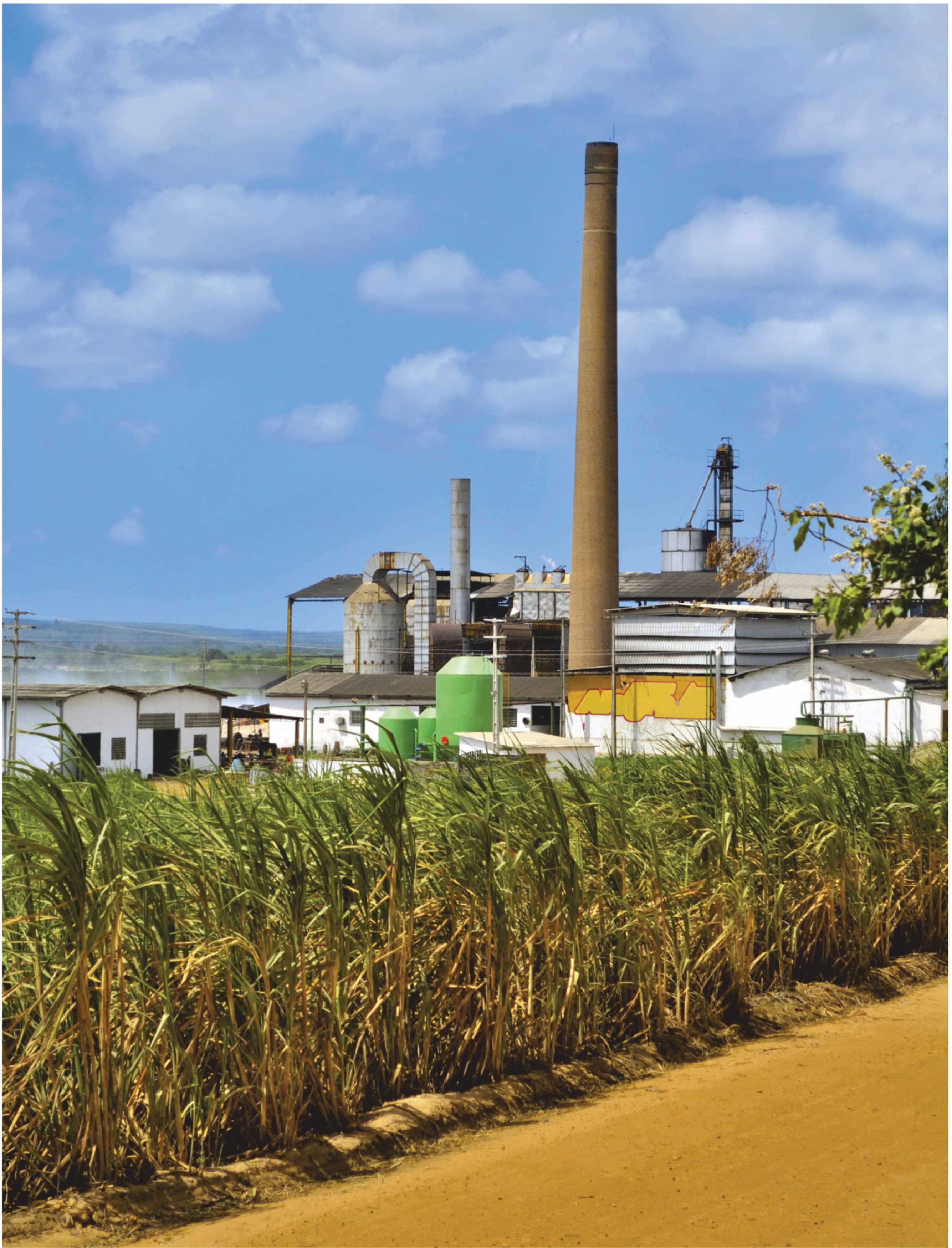

Sugar Industry Specialization

PREW provides custom-engineered solutions for the sugar industry, including specialized chain designs and advanced wear protection for optimized performance.

Manufacturing Industry

PREW delivers precision-driven manufacturing solutions, from high-performance components to scalable production systems, ensuring quality and reliability.

Automation Industry

PREW offers intelligent automation solutions to streamline industrial processes. Leveraging advanced control systems, we enhance productivity and consistency.

Food Processing Industry

PREW delivers food-grade conveyor solutions with easy-to-clean designs, offering reliable, safe, and efficient movement in high-demand processing environments.

Pharmaceutical Industry

PREW delivers food-grade conveyor solutions with easy-to-clean designs, offering reliable, safe, and efficient movement in high-demand processing environments

General Engineering

PREW supplies robust chains, belts, and rollers engineered for heavy-duty applications and continuous operation—enhancing reliability, safety, and efficiency in oil refineries, power plants, and the cement industry.

Power Your Business with PREW

63+ years of expertise. 350+ trusted partners. Precision solutions made for your industry.