Solutions We Provide

Industry-Leading Steel Processing

Experts: We provide customized metal processing solutions powered by advanced technology—ensuring unmatched precision, reliability, and on-time delivery for every project.

Inspection, Survey & Consultation

P. R. Engineering Works offers expert evaluations and strategic guidance to optimize sugar industry equipment—enhancing efficiency, performance, and reducing downtime.

Design & Drawing Services

We deliver precise technical drawings and design support, working closely with you to streamline fabrication, enhance development, and ensure optimal results.

Our Engineering Excellence

Laser Cutting Equipment

Advanced fiber-laser cutting systems

Press Technology

Mechanical press up to 300 tons

Welding Department

Robotic and manual welding capabilities

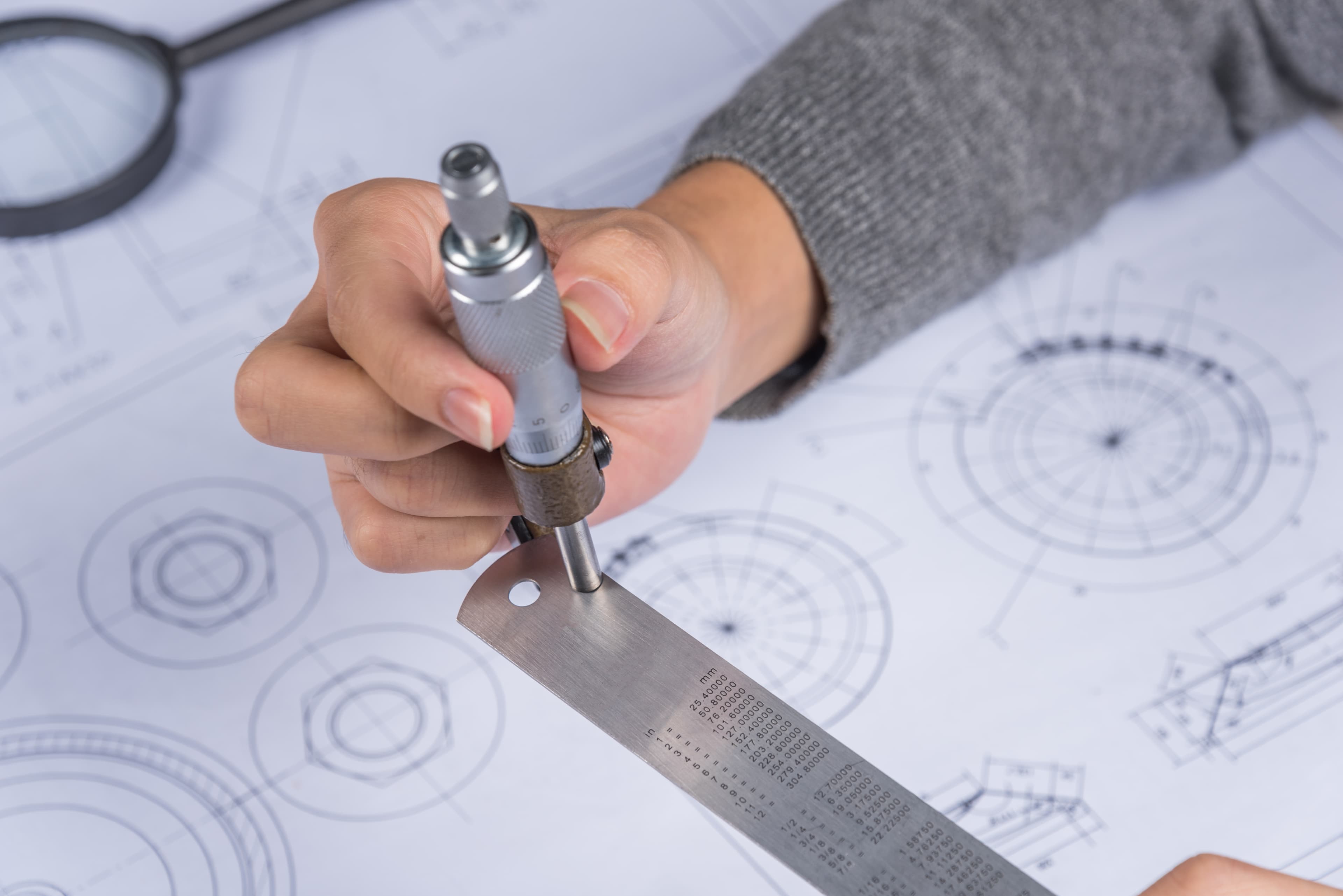

Quality Control

Precision measurement and inspection

Fabrication Floor

Large-scale production capabilities

Manufacturing Capabilities

Advanced technology meets rigorous quality standards for faster throughput and minimal waste

Laser Cutting Capabilities

- Mild & Carbon Steel: up to 22 mm

- Stainless Steel: up to 12 mm

- Bed Size: 3 m × 1.5 m

- High-precision, clean-edge profiling

Flame & Plasma Cutting

- Flame Cutting: up to 80 mm

- Plasma Cutting: up to 20 mm

- Ideal for thick materials

- Precision and speed focused

Press Technology

- CNC Press Brakes: Up to 220 tons

- 4000 mm length capability

- Compact CNC: 2000 mm gap

- Conventional: 50-300 tons

Welding & Fabrication

- Robotic welding systems

- Expert manual welding

- High-volume precision

- Custom component crafting

Why Choose P R Engineering Works

Leaders in laser profiling & fabrication with decades of expertise

ISO 9001:2015 Certified

Full compliance with international quality standards, monitored at every stage

Reliable Delivery

On-time delivery every time with rapid, reliable precision component manufacturing

Advanced Technology

Home to some of the most advanced laser systems in the country

Safety First

Operations designed to surpass global workplace safety standards

Lean Manufacturing

Real-time tracking from raw material to finished goods with minimal waste

Quality Assurance

Continuous process audits drive efficiency and consistency

SAFETY FIRST

We are dedicated to ensuring a healthy and safe environment for all employees, while also safeguarding contractors, customers, visitors, and any other individuals impacted by our operations.

Our commitment is realized through the assessment of significant risks, the design of safe work systems, and the elimination of hazards wherever reasonably practicable. This dedication is embedded in our company HSE policy is deeply ingrained in the daily culture of our business.

Unlock Your Solution Now

From assessment to action, we provide full-process support with minimized downtime and maximized efficiency.