Quality Policy & Objectives

We are Committed to become a Total Quality Oriented Organisation by Continually Improving our Processes to satisfy our Customer needs.

- To Deliver On-time & Quality Product as per Customer need

- Continually Improve Processes at all Levels and Functions

- Develop People Through Continuous Training

- To Achieve INR 500 Million of Sales by 2018

- Emphasis on Employee Safety

After Exact Requirement with Approved Drawing File We will Finalize the Quotation and we will Take Conformation On P.O. with exact Dispatch Date.

After Finalization of P.O We will Immediately Start Working on Purchasing of material , our Production Expert with our Planning Methods will start to Organizing Development Strategies to meet requirements.

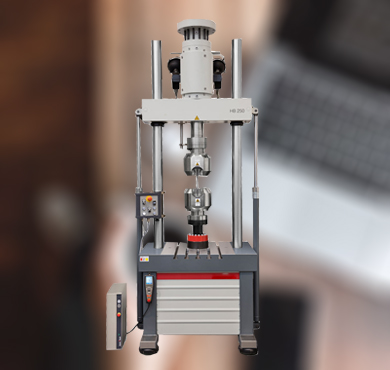

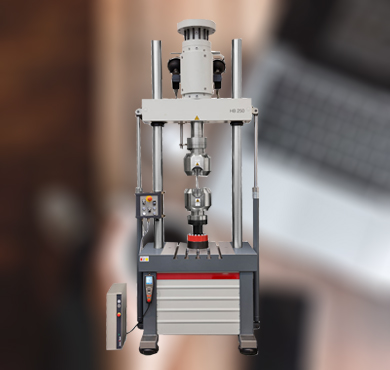

our every production steps is having strong S.O.P. as well as Inspection Methodology but after final finishing we are using CMM and UTM facilities to maximize the accuracy.

After Sucessful Inspection our Well Equipped Packing Manager with Automatic Packaging Machines Will Assure The Transportation Method will Deliver in Time With Maximum Protection to Products (jobs).